Ceramic lining is a protective system that uses engineered ceramic tiles to shield equipment from wear, impact, and corrosion. These tiles are made from advanced materials like alumina (Al₂O₃) and silicon carbide (SiC) that offer exceptional hardness and durability.

Ceramic tiles are precisely cut and bonded to equipment surfaces using industrial adhesives and grouts. Ceramic lining offer superior hardness compared to steel or rubber alone. They provide excellent chemical resistance and can handle extreme temperatures while maintaining structural integrity.

Ceramic linings are essential for protecting high-wear components in mining operations, especially in gold, iron ore, lithium, nickel, and mineral sands processing. They extend equipment life in abrasive and high-impact environments where metal fails fast. In slurry systems, ceramic-lined pipelines handle tailings, concentrates, and abrasive slurries with minimal wear. Cyclones, classifiers, and separators stay efficient longer with lined interiors. Ore chutes, launders, and hoppers benefit from reduced abrasion and consistent flow. Pumps, vibrating feeders, and screens are shielded from continuous impact and erosion. High-impact zones like drop boxes and conveyor beds are reinforced to handle velocity changes. For complex setups, modular ceramic panels are custom-fit to deliver targeted, long-lasting protection.

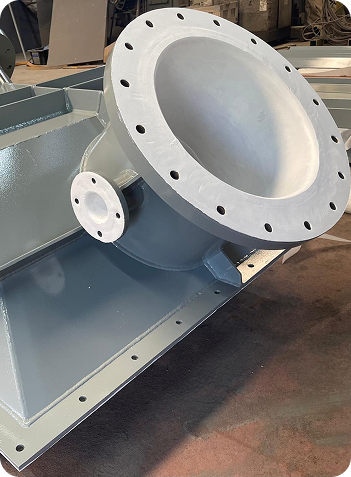

Full-service workshop handling ceramic lining with precision installation. Fabricated, bonded, and tested by experienced specialists.

Installation methods vary by equipment type and include direct bonding, spin casting, or fitting engineered ceramic shapes. Installations are customised to match wear patterns and loads for a precise, long-lasting fit.

Ceramics outperform rubber, steel, and glass in abrasive, high-temp, and chemically harsh environments, lasting longer, reducing maintenance, and lowering total plant costs.

RiozLek uses CNC machining and in-house design to tailor systems to equipment geometry and site-specific wear patterns. Options include monolithic, rubber-backed, or steel-backed tiles, engineered for fit and performance.

Ceramics are installed using adhesives, welding, bolting, or as pre-cast inserts, depending on load and equipment design. CNC-cut, modular systems allow fast, low-disruption replacements, ideal for continuous operations.