Blasting and painting are essential surface treatment processes used to prepare, protect, and preserve critical equipment and infrastructure. Blasting removes contaminants, corrosion, and old coatings, creating a surface profile that enhances adhesion for protective paints and linings. It’s used for industrial cleaning, structural prep, and corrosion control.

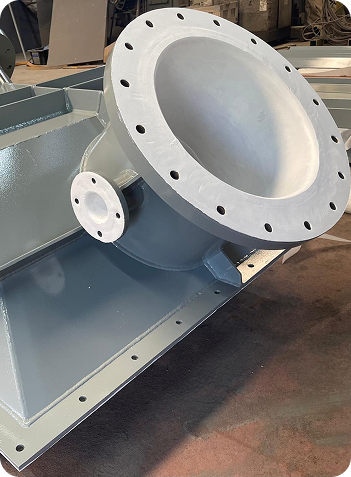

Painting involves applying specialised industrial coatings, such as epoxy, polyurethane, or zinc-rich primers, to protect metal assets from corrosion, abrasion, UV, and chemical attack. This process is critical for both structural integrity and long-term performance of equipment in harsh mine site conditions.

Blasting and painting play a critical role in asset protection across Western Australia’s mining sectors, including iron ore, gold, lithium, and mineral processing. Surface preparation via abrasive blasting is essential before applying rubber or ceramic linings, ensuring proper adhesion and long-term performance. Industrial coatings are applied to platework and fabricated components to guard against corrosion, chemical exposure, and wear, especially in harsh outdoor environments. Structural steel and piping systems, including beams, tanks, pipe spools, chutes, and bollards, are blasted and painted to prevent rust and degradation in high-exposure mining areas. Equipment refurbishment is another key application, components like axles, motors, handrails, walkways, radiators, and platforms are stripped, blasted, and recoated to restore integrity and extend service life.

Full-service facility with dedicated blasting bays, spray booths, and temperature-controlled curing rooms.

Yes, when done by trained providers using the right abrasive media and pressure, blasting cleans without damaging the substrate. Always ask the provider how they adjust technique per material.

If there is rust or thick old paint, blasting or abrasive prep is recommended to ensure adhesion. For minor flaking or scratches, sanding or chemical stripping may suffice

Systems commonly include zinc primers, high-build epoxy basecoats, polyurethane topcoats, marine-grade films and intumescent layers. Selection depends on exposure to UV, chemicals, abrasion, humidity or heat

Surface prep is matched to substrate and corrosion severity. Garnet or steel grit is used for heavy rust or welded steel. Dustless blasting for concrete or sensitive surfaces. Coating systems like zinc primers, epoxy build coats, and top-coats are selected per environment.