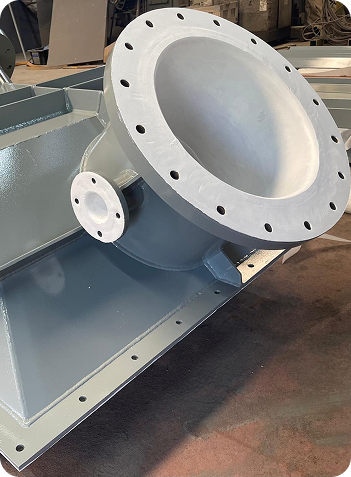

Rubber lining is the process of applying an industrial-grade rubber layer, either natural or synthetic, onto metal or concrete surfaces. Like Tanks, hoppers, pipes, and other contact-heavy equipment. This barrier protects against corrosion, abrasion, and chemical degradation. It’s widely used in industries where operational integrity and chemical containment are non-negotiable.

The lining thickness varies based on usage. From a few millimeters for general protection to multiple layers for high-abuse environments. The goal is simple, to preserve structural integrity and prevent expensive failures. In short, it’s cheaper to line a tank than to replace it.

The industries we serve, mining, chemical processing, water treatment, and heavy manufacturing, operate under brutal conditions. Equipment is constantly exposed to acids, alkalis, abrasion, and impact. When left unprotected, metal structures degrade fast, forcing unexpected shutdowns, expensive repairs, and full replacements far too often.

Rubber lining is not a temporary patch. It’s an engineered defense system. It extends the life of tanks, pipes, launders, and screens by creating an impermeable barrier between your infrastructure and the materials that damage it. It’s the smart, proactive way to cut costs. Our precision-engineered rubber lining creates an impenetrable barrier between your valuable equipment and corrosive forces, extending lifespan by 500% while eliminating contamination risks.

Our advanced workshop facilities are equipped with hi-tech technology and staffed by expert technicians to deliver superior rubber lining solutions

Our rubber lining solutions typically last 10-15 years depending on the application, operating conditions, and maintenance practices. In many cases, properly maintained rubber lining can extend equipment life by 3-5 times compared to unprotected surfaces.

Our experienced team conducts a thorough assessment of your equipment, operating conditions, and performance requirements. We evaluate factors like the type of material being processed, operating temperature, impact levels, chemical exposure, and wear patterns. Based on this analysis, we recommend the most suitable rubber compound, thickness, and installation method to optimise performance and cost-effectiveness for your specific application.

Rubber linings offer several key advantages: excellent impact absorption and vibration dampening, superior chemical resistance, flexibility that accommodates thermal expansion, noise reduction, easy installation and repair, cost-effectiveness compared to frequent steel replacement, and the ability to be customized for specific applications. Unlike hard linings, rubber can absorb shock and distribute impact forces, significantly extending equipment life.

Absolutely. We provide custom rubber lining solutions tailored to your specific requirements. Thickness options range from 6mm to 75mm, and we can formulate custom compounds optimized for your operating conditions. Whether you need enhanced chemical resistance, higher temperature capability, improved abrasion resistance, or specific hardness levels, our technical team can develop the ideal solution for your application.